In the bustling and vibrant city of New York, keeping your products fresh is essential for any food and beverage-related business. Whether you run a restaurant, a café, a grocery store, or any other type of establishment, maintaining your cold room in optimal conditions is crucial to ensure the quality and safety of your products. Here are some practical tips for keeping your cold room in New York and ensuring your products remain fresh at all times.

EXCELLENTTrustindex verifies that the original source of the review is Google. Excellent workers, I recommend them 100%, I tell you that they are super responsible and the best of all is that work is guaranteed.👌☺️Posted onTrustindex verifies that the original source of the review is Google. On point, Always. Reliable and good pricing. Service is good! Ask for MarcusPosted onTrustindex verifies that the original source of the review is Google. Best workers in the New York City they do any job you need them to doPosted onTrustindex verifies that the original source of the review is Google. The repair service for my water heater was fast and effective. I will definitely use their services again in the future!

- Keep the Equipment in Good Condition:

The first step in maintaining your cold room in New York is to ensure that all your equipment is in good working order. This includes compressors, fans, temperature controllers, and any other key components. Conduct regular inspections and maintenance programs to identify and address any issues before they affect the quality of your products.

- Monitor Temperature and Humidity:

Maintaining a constant temperature in your cold room is crucial to ensuring your products are properly preserved. In New York, where temperatures can vary considerably throughout the year, it’s important to adjust the refrigeration system according to weather conditions. Additionally, control humidity to prevent condensation, which can affect the quality of your products.

- Efficiently Organize Your Space:

Efficient organization of space in your cold room will not only help maximize storage capacity but also facilitate airflow and circulation within the space. Make sure to leave enough space between products to allow air to circulate freely and avoid blocking ventilation grilles.

- Regularly Inspect Doors and Seals:

Air leaks can compromise the efficiency of your cold room and lead to increased energy consumption. Therefore, it’s important to regularly inspect doors and seals for any signs of wear or damage. Adjust or replace seals and doors as needed to ensure a tight seal.

- Maintain Cleanliness and Hygiene:

Keeping your cold room clean and tidy is crucial for ensuring food safety and the quality of your products. Schedule regular cleanings to remove any buildup of dirt, grease, or residues, and make sure to follow cleaning and disinfection protocols recommended by health authorities.

- Train Your Staff:

Last but not least, train your staff on the importance of properly maintaining a cold room. Provide training on how to operate and maintain equipment correctly, as well as on food safety procedures and hygiene standards. A well-trained team will be crucial to the success of your operation.

In summary, maintaining your cold room in New York in optimal conditions requires a proactive and diligent approach. From keeping equipment in good condition to monitoring temperature and humidity, to efficiently organizing space and conducting regular maintenance, every detail matters when it comes to ensuring the freshness and quality of your products. With these practical tips, you’ll be able to keep your products fresh and safe at all times, contributing to the success and reputation of your business in New York’s demanding food and beverage scene.

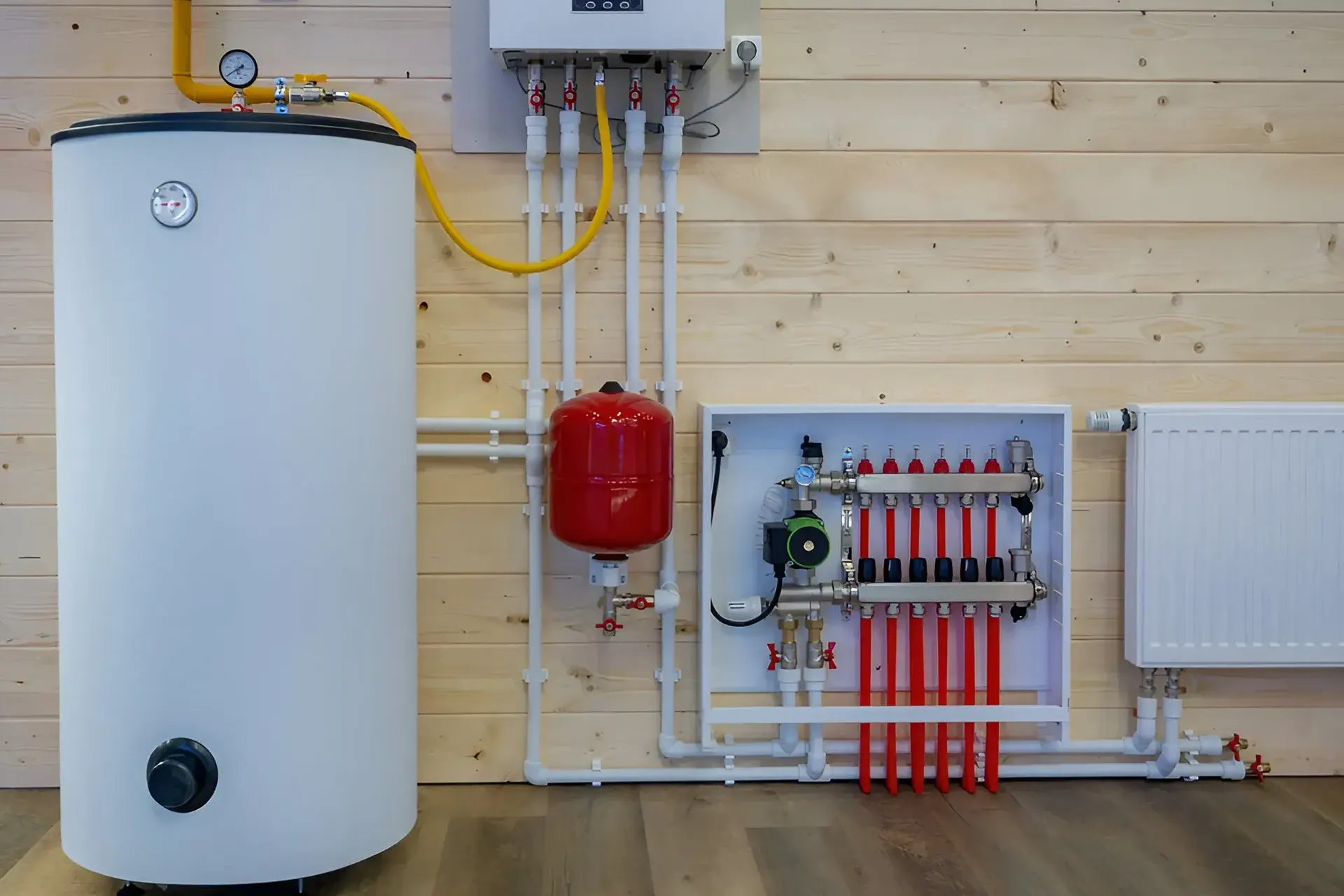

Installation and Repair of Water Heaters